RV Energy Management

Energy Management is simple – you just need to make sure that you don’t use any more power than is available. Battery power is finite. Eventually it’ll run out. By minimizing how many lights are on and the time they are on, battery life can be extended. Eventually you’ll need to recharge them, either by driving the coach or by running the generator. Adding extra batteries can extend that runtime as can the addition of solar panels. If you are plugged into shore power this isn’t an issue because your converter or inverter/charger will keep them charged while you use them.

AC power is a bit different. Unlike battery power, there is no reserve to draw from. You are limited to the total current capacity of your shore power pedestal or your generator’s capacity. Generators are generally sized for that particular coach so you should be able to run whatever loads you need to operate without exceeding the generator’s capacity. Of course there are exceptions where an undersized generator was specified in that particular coach rather than choosing the optional generator but those are the exception, not the rule.

Shore power pedestals vary in size. If you are running a small 20 amp cord to your RV from someone’s home you’ll be very limited as to what you can run. Battery chargers vary in current draw as to how many battery amps they are outputting. A battery charger that is outputting a full 100 amp bulk charge at 12 volts will be drawing 10 amps of 120 volt AC power. That can take up one half of your 20 amp circuit, which doesn’t leave a whole lot left. Many inverter/chargers have a setting on the remote control panel to define the shore power service. If you define the shore power at a lower level, say 20 amps, then it will limit the 120 volt power that the battery charger uses so that you can have more left to run other 120 volt items. You will need to manually set this once you are plugged into a smaller shore power pedestal.

A typical RV pedestal with multiple 50-30-20-amp receptacles

In the above image we can see three receptacles. This is a typical 50 amp pedestal which features a 50 amp, 30 amp, and 20 amp outlets. This pedestal allows virtually any type of RV to be serviced with power. The 50 amp outlet is a 120/240 volt split-phase outlet, capable of 12,000 watts of total power. If you have an RV with 50 amp service you should have no problems powering your RV’s electrical appliances when plugged into a 50 amp outlet. Older pedestals may only be configured with a 30 amp outlet however. This is a single pole 120 volt feed, capable of 3,600 watts of total power. You can adapt your 50 amp coach to this 30 amp outlet via a dogbone adaptor but you will be severely limited in just how much you can run in your RV. If the battery charger is pulling 5 amps and your two air conditioners are pulling 12 amps each you’ll be drawing a total of 29 amps. All it takes is for the electric water heater element to kick in or someone turning on the microwave and you’ll trip the pedestal breaker and you’ll be making a trip out to the pedestal to reset it, which of course always happens when it’s raining.

Manual Energy Management

Manual energy management entails turning off some loads so that you can turn on others. If you really need to get hot water it would be best to use the propane burner instead of electric if it’s hot out. If you need to use the microwave for a bit then you’ll have to shut down one of the air conditioners so that amperage can be used by the microwave temporarily. Eventually this gets to be tiring and you’ll either find places to stay at that only have a 50 amp service or you’ll wish you had an automatic energy system.

RV Automatic Energy Management Systems

An Energy Management System (EMS) automatically performs the circuit switching procedures for you. Do not confuse a true EMS system with surge protection. Some name brand surge protectors use the term EMS in their models and descriptions. In a way, this is true because they do more than stop surges. They also protect from low or high voltage but they are still part of the surge protectors category. True EMS systems do not consider voltage levels. They only monitor the amperage draw and perform shedding of various circuits to keep the total power consumption beneath the pedestal breaker rating.

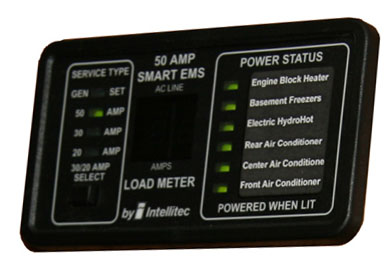

The remote display panel from the Intellitec Energy Management System

Let’s assume that you want to run two air conditioners (at 12 amps each), the electric water heater (at 10 amps), and your battery charger (4 amps in float mode). That’s a total of 38 amps, which won’t work on a 30 amp service. We’ve already switched the refrigerator over to propane so that’s out of the equation. The EMS will shed the first available load, which is the water heater so that everything else can run. You’ll then be drawing 28 amps. When the thermostat kicks out one air conditioner the load will be reduced to 16 amps so power to the hot water heater will now be restored and the new load will be 26 amps. If someone turns on the microwave and needs another 11 amps, the total draw would be 37 amps so the EMS will shed the next item on the list so now the water heater and one air conditioner will be shed. When the microwave is finished the next priority level circuit will be restored, which in this case is the air conditioner. By doing this the EMS prevents the pedestal breaker from tripping by limiting the total current.

A more recent entry into the energy management field is an EMS by Precision Circuits, Inc. This unit operates in similar fashion to the Intellitec system except it takes it one step farther. It actually interfaces with the inverter and will trigger the inverter so that it powers its output circuits rather than passing through shore power. This way when someone operates the microwave the inverter will power it rather than shedding a circuit. Should this continue for a long time the EMS will stop the inverter to prevent running the batteries too low and will shed circuits like a traditional EMS. This offers the benefit of not having to shut down your air conditioner on a hot day if other loads are going in and out. In order for this feature to function the PCI EMS must be connected to a Magnum inverter. A number of manufacturers are now using this more sophisticated system. An additional remote display panel is required – one for the inverter and one for the EMS.

Surge Suppression: Protect against low or high voltage

Technically, a surge protector protects against surges in electrical power. But surge protectors as used in RVs do far more. In addition to surge suppression, the most popular surge protectors also protect against low or high voltage levels. Low voltage can be a common occurrence in campgrounds that have added sites over the years but failed to upgrade their electrical grid to keep pace with the increased demand. Low voltage can cause quite a bit of damage so it’s important that you purchase a quality surge protector that includes over and under voltage protection as well. First let’s define just what an electrical surge is.

An electrical surge is where the incoming voltage rises to a point significantly higher than what it’s supposed to be. A voltage spike is similar but a spike is defined as lasting for one or two nanoseconds whereas a surge lasts three nanoseconds or longer. If the voltage is high enough it can damage your electrical devices. Earlier we talked about electrical voltage and how it is a measurement of pressure. If you get a sudden surge in water pressure you are apt to blow a hole in your fresh water supply hose but if you get a sudden surge in electrical pressure you are going to blow some electrical devices or sensitive electronics equipment. Surge protectors use metal oxide varistors, commonly called MOVs. An MOV does nothing at normal voltage levels but when the voltage rises to an unsafe level the MOV will short that power to ground to protect any downstream electrical equipment.

Importance of a Quality Surge Protector

A quality surge protector designed for RV use will also have both over and under voltage protection. Overvoltage isn’t a real common problem in an RV park but it is a distinct possibility. Excess voltage will do the same damage as a surge except it’s generally not as high a peak voltage but it lasts for much longer. The most frequent condition is low voltage at the campground pedestal. You may arrive at your campsite early and check your pedestal voltage with a voltmeter and find it within tolerance. However, once other campers arrive and start to fire up their air conditioners the voltage is likely to drop. Without an automatic surge protector you would have no protection against low voltage damage to your coach unless you constantly monitor the incoming voltage. A good surge protector will disconnect power to the coach should either low voltage or high voltage conditions appear. At that time you would have the option of waiting it out, running your generator, or using an Autoformer to boost the incoming voltage – more on that later. Quality surge protectors for RVs are available from Surge Guard and Progressive Industries and are two well respected companies that offer their product through most major RV accessory sales outlets.

A Surge Guard portable surge protector

A 50-amp portable surge protector from Progressive Industries

Benefits and Disadvantages of Portable Surge Protectors

In the images above, we can see two portable surge protectors. Portable units have the advantage of being able to be readily moved from one RV to another. This makes for a zero installation setup with no rewiring. Just plug it into the campground pedestal and plug the RV’s power cord into the surge protector.

The disadvantages are that it is out in the weather and could get stolen or vandalized. There are locking kits available to lock them to the pedestal but then you are trading the convenience of not having the initial install versus connecting it and securing it to the pedestal every time you go camping. If the pedestal’s receptacle is very low to the ground it’s possible that the portable unit may not fit because of the right angle plug and the bulk of the unit that needs to hang down from the outlet.

One last caveat is that the hard wired units sometimes offer a remote display option so that you can monitor the incoming power from inside the coach. With a portable unit you won’t be able to utilize that option. The actual protection levels of the portable units are generally the same as their counterparts in the hard-wired segment so there’s no advantage or disadvantage there.

Surge Guard 50-amp hardwired surge protector

A 50-amp Surge Protector from Progressive Industries

Surge Protector Installation

Hard-wired devices do take a bit of installation labor but it’s not that difficult. You simply mount the unit in the same electrical compartment that your RV’s cord is located in. Remove the power cord from the transfer switch and connect the cord to the surge protector’s input terminals. Then run a short whip cord from the surge protector’s output to the transfer switch and you’re all set. Some RV owners choose to just cut 2-3′ off the end of the power cord while some choose to buy another short chunk of cord from a home improvement store. If you have a power cord reel you’ll undoubtedly be buying a new whip. If your surge protector includes a remote display you will have to find a location for that display, mount it, and then connect it with a standard RJ11 modular phone cable. A cable is generally supplied but if you want to run a longer distance you may have to make a new, longer cable to reach the remote display panel.

The Best Energy Management System for Your RV

Surges are rated in Joules. The bigger the surge, the higher the number, so you want to get a surge protector with the highest possible rating. The popular Surge Guard 34560 is rated to handle up to 1,750 Joules of power surge. It will shut down power to the coach if the voltage falls below 102 Volts or is higher than 132 Volts. Various LEDs will inform you whether the receptacle is properly wired or has a bad ground, reversed polarity, or open neutral. If it shuts down the power due to low or high voltage or an open neutral wire it will reset itself once the power returns to within tolerances. There will be a two minute, 15 second delay before power is re-energized though to allow any air conditioner time to bleed off their head pressure. If you decide that you want to bypass the voltage cutouts feature and allow power through you can defeat the unit by turning a key switch. In this mode you will still have surge suppression, however. Surge Guard also makes automatic transfer switches with built in surge protection and low voltage protection. These transfer switches are becoming very popular in recent diesel pushers due to their ability to also communicate with a multiplexed network control panel.

The Progressive EMS-HW50C is the gold standard of surge protectors. It’s rated to handle up to 3,560 Joules of surge. Low voltage cutoff occurs at 104 Volts and high voltage cutoff occurs at 132 Volts. It comes with a remote LED display that is very easy to read. In addition to displaying the incoming voltage of both poles it will also display the amperage draw on each pole as well as the frequency in Hertz. If any pedestal mis-wiring is present or any shutdown has occurred the LED display will display a 2 digit trouble code that defines the problem according to the chart that is printed on the unit as well as in the owner’s manual. The remote display can be mounted inside the coach or in the basement compartment. In this way it’s handy to locate the EMS-HW50C near the back of the compartment where it’s easy to wire and still have the remote display located near the front of the compartment where it is easy to view. The bright LED is easy to read in bright sunlight and a bypass switch is located on the remote display to bypass the power shutdown function, just like in the Surge Guard above. You have the choice of selecting either a 15 second power-on delay or a 136 second delay. Most modern air conditioners have a built in two minute restart delay so 15 seconds is the normal selection. You can also buy a second remote display that allows you to mount one in the basement and one inside the coach if you desire.

While the EMS-HW50C is the old standard, Progressive Industries also make the EMS-LCHW50 surge protector. The “LC” stands for Liquid Crystal display. Instead of a remote LED display, the LC series uses an integral liquid crystal display that is located right in the cover of the unit. The protection level is the same as its big brother but, depending on where the unit is mounted, you may have more problems in viewing the display. LCD screens just aren’t as bright as LEDs and dark places and bright places are not their friends. Coupled with the fact that the remote LED display can be located anywhere and the LED holds a huge advantage. Still, the LC series does hold a $50 price advantage over its more costly brother.